WHAT WE DO

WE ARE NOT JUST SUPPLIERS, WE ARE ABOVE ALL PARTNERS

PRODUCT ENGINEERING

The heart of the company, the Design Office, made up of four professionals, is responsible for the study and design of the parts to be made, through to the design of the mould.

DIE CASTING SIMULATION

Thanks to a die casting simulation software, we have a valid support for the design of Zamak die casting moulds.

3D

A fast 3D scanning and printing service, with latest generation tools, to meet the needs of a market increasingly looking for quality and precision.

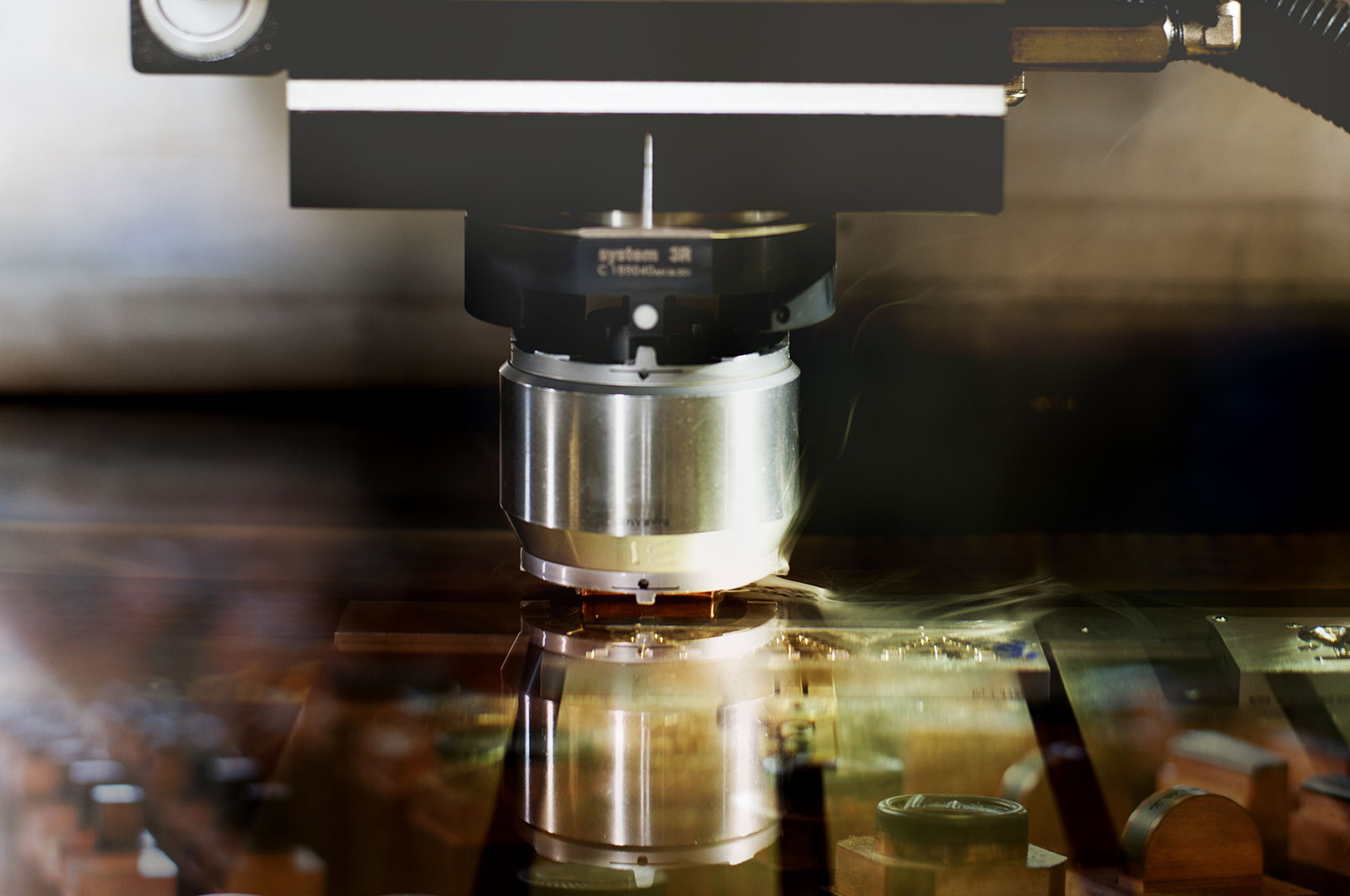

MOULDS

We boast many years of experience in the construction of small to medium-sized steel moulds for Zamak die-casting and plastic moulding. Our constantly updated machinery, our state-of-the-art tools and equipment, together with quality raw materials, such as Voestalpine Group steels, certify the excellent quality of our moulds. We do not want to be just a supplier of moulds: we are a reliable partner, a point of reference for those who need a mould, which is designed and manufactured with care and in increasingly fast times.

We are currently working with the best technologies available on the market; we are always looking for new solutions to improve our workmanship, thus providing our customers with new solutions to simplify their production process.

We are working for the future, always aiming at new quality targets: our goal is to develop new solutions, with moulds that can increasingly work in a safe way, combined with handling robots for gripping the die-cast part. We plan to invest in new technologies such as “Additive Manufacturing”.

All this without ever neglecting the importance of personal contact, the propensity for a collaborative relationship, and special attention to the needs of the customer. Even today, after more than forty years, this remains our credo.